When was the last time that you took a flight? Maybe you went for a holiday to the seaside or some other interesting place, or to see relatives living abroad. Flying is no longer the luxury that is used to be. You will fly not only more frequently than your parents (not to mention your grandparents!) but also further. We are no longer surprised to see groups of tourists from East Asia (Japan, Korea, and also China) in Bratislava’s historical city centre, and this is only the beginning. Every day more people from countries like China and India, with a joint population of more than 5 times that of the European Union, are able to afford a flight. This is a lot of kerosene being burned in aeroplane turbines. What happens with the emissions?

The European Union has decided to drastically reduce the emissions of commercial flights. The ACARE Flightpath 2050 emission targets seek reductions in carbon dioxide by 75%, nitrogen oxides and particulates by 90%, and noise by 65% compared to the year 2000. Drastic reductions require drastic improvements. Electric and hybrid aeroplanes could enable such a radical reduction. However, these new aeroplanes would require very powerful and light electric motors, which do not exist.

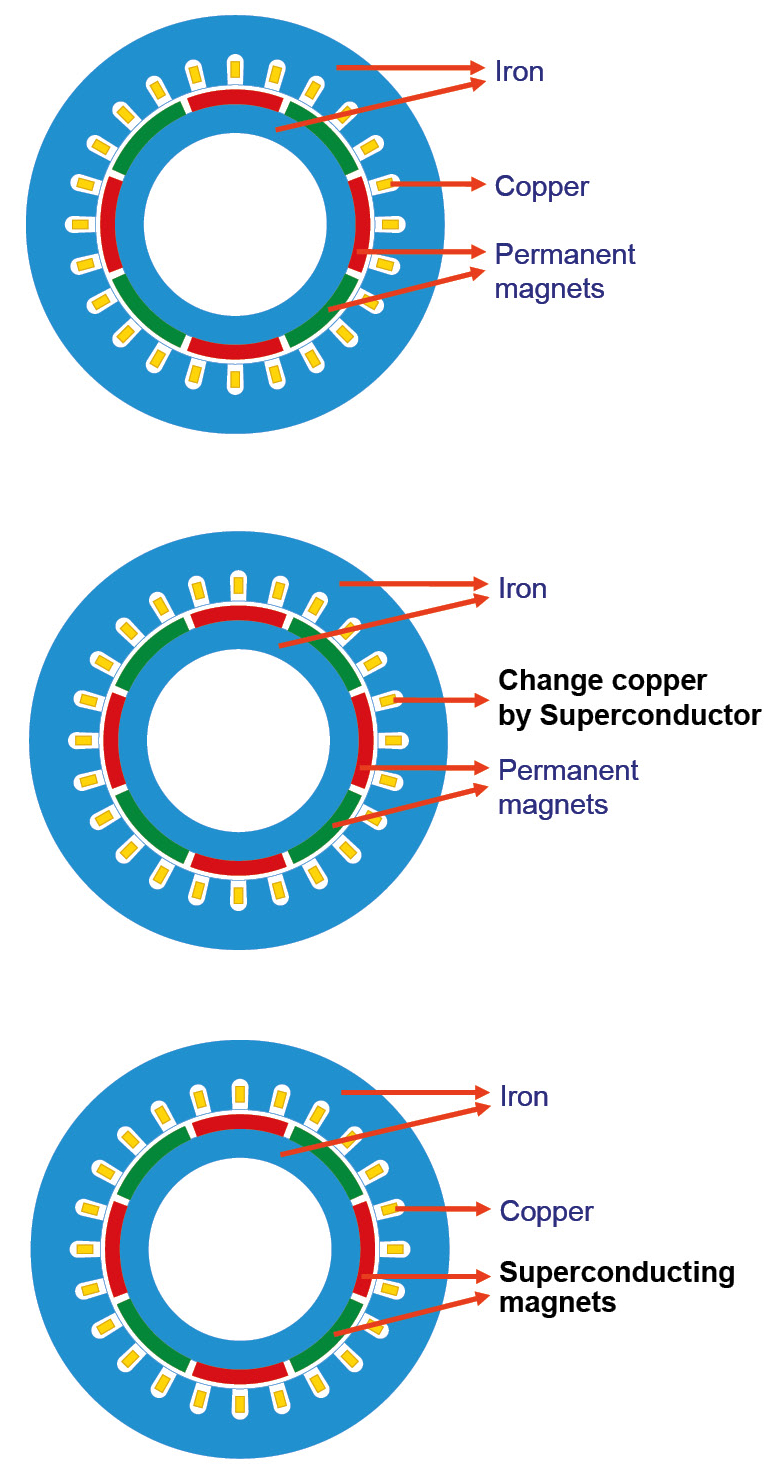

Typical electric motors contain wiring (a stator, usually made of copper wire and iron) and a moving axis (rotor) made of magnets.  In the stator, superconductors can carry much higher current densities than copper: a bacteria-thick layer of 2 µm on a 4 mm wide metal tape can carry up to 2000 A, around 60 times the typical maximum current from the grid to a household. There is only one drawback: superconductors need to be cooled to very low temperatures, the lower the better. High-temperature superconductors like REBCO start to work below 90 K (-183 °C) but you might need temperatures as low as 20 K (-253 °C) to boost their performance enough. Nevertheless, that temperature could be achieved with liquid hydrogen, which might serve also as fuel. In addition, we could replace conventional magnets with superconducting ones, generating stronger magnetic fields. The world record, now held by the University of Cambridge, is of 17.7 T, roughly 10 times more than that of the strongest conventional magnets.

In the stator, superconductors can carry much higher current densities than copper: a bacteria-thick layer of 2 µm on a 4 mm wide metal tape can carry up to 2000 A, around 60 times the typical maximum current from the grid to a household. There is only one drawback: superconductors need to be cooled to very low temperatures, the lower the better. High-temperature superconductors like REBCO start to work below 90 K (-183 °C) but you might need temperatures as low as 20 K (-253 °C) to boost their performance enough. Nevertheless, that temperature could be achieved with liquid hydrogen, which might serve also as fuel. In addition, we could replace conventional magnets with superconducting ones, generating stronger magnetic fields. The world record, now held by the University of Cambridge, is of 17.7 T, roughly 10 times more than that of the strongest conventional magnets.

The Institute of Electrical Engineering of the Slovak Academy of Sciences participates in a European project (Horizon 2020 program, project ASuMED) aimed to construct a laboratory-scale motor of 1 MW with 20 kW/kg power density. This motor, weighing around 50 kg, could replace the engine of your car, but with more than 10 times the power. The motor must also be very efficient (99.9%) in order to save fuel and reduce heating. Perhaps the most famous partner of the project is Rolls-Royce PLC, which produces engines for commercial aeroplanes. However, the coordinator and main partner is OSWALD Elektromotoren, a relatively small German company producing high-performance electric motors.

Apart from top German research centres and universities (Karlsruhe Institute of Technoloty and Hochschule Aschaffenburg), the University of Cambridge also has an important role in the development of superconducting magnets. DEMACO is designing the cryostat of the motor. Air Liquide, a cryogenics expert with extensive experience in aerospace, studies a cryocooler system enabling the motor to maintain a cryogenic temperature. SuperOx provides the superconducting tape. Airbus and Siemens also advise the project on general specifications.

“Our Institute is happy to participate in computer electro-magnetic modelling of the superconducting parts, as well as some laboratory measurements. The software that we developed not only out-performs commercial software for this purpose but also allows us to use the super-computer AUREL in the Slovak Academy of Sciences, as well as possible future super-computers. These computations will enable the project to optimize the superconducting parts and find ways to increase the efficiency and power density of the motor,“ said Dr. Pardo.

„It was a huge effort to design this motor, with so many new ideas in the superconducting parts and cooling system, specially taking into account that the rotor turns very fast. Now, the most important task is to build the motor. We are confident that by 2020 the motor will work very well and, maybe, one day you could be flying on futuristic, clean and quiet aeroplanes with superconducting motors,“ Dr. Pardo finished the interview with hope.

Dr. Enric Pardo, Institute of Electrical Engineering, Slovak Academy of Sciences